Written by Dmitry Zhavoronkov; Originally appeared on FlotProm.ru; Translated by AlexD exclusively for SouthFront

The creation in 2017 of United Shipbuilding Corporation, and a year later, United Engine Corporation, as well as the industry trend to combine enterprises into holdings and financial and industrial groups (“Transmashholding”, “GAZ Group”, “Eurotrade”, etc.) made it possible to talk about the formation of a united approach to ship engine building. However, the coordination between the Ministry of Industry, Defence, Navy, corporations, design bureaux, shipyards and diesel manufacturers, remains unsatisfactory. Several sources from shipyards, “Yantar”, the “Zelenodolsk” plant in the name of Gorky, “Northern Shipyard”, “Almaz” central marine design bureau and “Nevsky” design bureau, described this to Mil.Press FlotProm. After all, despite all the declared successes, “diesel pain” created problems for almost all ships and Navy vessels under construction.

In the public sphere, the enterprise management, especially those belonging to large state corporations, is reluctant to comment on existing problems. The alarm is sounded at the level of commanders of machine groups, mechanical engineers and specialists of enterprises repairing diesel engines. The owners of private shipyards or diesel plants are at a loss.

The situation with diesel engines is well illustrated by the draft strategy for the development of the shipbuilding industry up to 2035, published by the Ministry of Industry and Trade on June 28.

The authors of the strategy called the situation in the production of power equipment for ships and vessels “especially critical”; we are talking about diesel engines, diesel generators, gas turbine engines, etc.

The United Engine Corporation (UEC) in its 2017 annual report completely closed the data on the progress in the production of gas turbine engines. But the corporation promises to cover the fleet’s need for gas turbine engines. As reported to the publication in May 2018 in the press service UEC-Saturn, the Russian Navy will receive the first serial domestic gas turbine engines in 2019.

Only a dozen Russian companies can produce ship diesel engines and their production potential is well known. The editors of Mil.Press FlotProm together with experts tried to find solutions to the diesel crisis.

The diesel engines for the Navy can, very conveniently, be divided into three main groups: engines for “small fleets” of boats and very small ships, for ships with displacement of up to one thousand tons, and larger ships. In the latter case, diesel is often used in the power generating system along with a gas turbine engine. Reducers also play an important role.

“Where there are no analogues”: a small fleet is waiting for specialised developments of diesel engines.

On the way “from small to large” we are immediately disappointed. For very small motor ships and boats (up to 5-8 metres) there are simply no Russian engine options. With gasoline engines it is the same situation, so manufacturers have no alternative but to choose foreign models. Thus, the designer and CEO of the private shipyard Kompan Marine Aleksandr Taranenko told the publication that he would be happy to use Russian diesel engines for his projects, but today in the world “in fact there are no alternatives to the Japanese Kubota block, the majority of leading companies are created on its basis”.

One of the systemic problems Taranendo considers is the “vicious Soviet practice of creating a ship or boat around a specific motor”. Weak characteristics of the domestic power generating systems restricted the capacity of the ships. The engine should be selected for the parameters of the vessel, and the absence of Russian manufacturers in this segment automatically forces designers to lay in the project of the vessel a foreign engine.

In general, for combat boats, diesel engines are precisely needed, as they can provide relatively long runs.

A possible solution here is the skilful “maritinising” of automobile engines and the return of Russian manufacturers to the market of outboard motors. The latter is impossible without state aid, as well as without a meaningful strategy in the field of the “small fleet” as a whole. The absence of such a strategy, its causes and consequences Mil.Press FlotProm considered in detail in the article “The Navy is not Exchanged for Trifles: There is no one at the State Level to Think about Boats”. The second approach, more understandable for business, is to create the production of engines based on popular foreign cylinder blocks. The editors of Mil.Press FlotProm are aware of the ongoing negotiations of Russian industrialists with foreign partners on the creation of such joint ventures in recent years. However, such projects remain high-risk investments, which are not ready for entrepreneurs without state support in the form of financing of development work.

“The Goal is to “maritinise” YAMZ-530”

Ships with a length of 8 to 12 metres have a good chance of getting a decent Russian engine. We are talking about the “maritinising” of diesel engines of the YAMZ-530 family from the public joint stock company (PJSC) “Avtodizel” (Yaroslavl motor plant).

In-line diesel engines of the YAMZ-530 family and the V-shaped YAMZ-850 are planned to be used on boats and small Navy ships. This was reported to Mil.Press FlotProm by two independent industry sources familiar with the situation.

For one of the future vessels, the engines of the 530 family will be modified as well as boosted, the source added. The relevant research and development work (R&D) began at the end of 2017.

Another source added that before using YAMZ-530 engines as marine engines, they would increase the allocation of their components. He also noted that the “maritinisation” is beneficial to the manufacturer, as it will increase the production of diesel engines.

As reported by Mil.Press FlotProm in the press service of the PJSC “Avtodizel”, the company plans to increase the share of Russian components in the engines of the YAMZ-530 family to 80% in 2018. In 2015, this figure was 65%, and in 2017 it was 77%, the company added. The manufacturer assured that the engine fully meets the requirements of “Made in Russia”, developed by the Ministry of Industry and Trade, but the company refused to comment on the prospects of “maritinising” the “530” family due to its military specifics.

A source in the industry, who wished to remain anonymous, raised in an interview with Mil.Press FlotProm the prospects of “maritinisation” of the YAMZ-530 engines. According to him, these diesels are quite modern and suitable for use on boats after certain changes in the design. At the same time, he expressed concern about the share of Russian components in this family.

Specialists of other Russian enterprises work on the YAMZ-530 ship versions. One of the projects involves the installation of a “maritinised” version of the diesel engine on a promising landing and assault boat for the Navy.

One of the engine problems that remains is the cooling and only 300-hour service life before repairs. For diesel engines, this is very critical because of the high compression: at some point, the temperature skew leads to a gap in the engine, according to what Aleksandr Taranenko mentioned to the publication. Thus, until the successful “maritinisation” of the YAMZ-530 in this class of vessels for the Navy, the use of foreign diesel engines remains uncontested.

“To Replace the Chinese”: Russian Ships, Russian Engines

The choice of foreign engines for ships and vessels of the Navy can result in a series of problems and long-term disruption of delivery. It happened with the power generating systems of Project 21980 “Grachnok” boats and the small rocket ship Project 21631. That said, ultimately the “import-substituting” decision to install Russian engines was taken. So was the game worth the candle, and why waste time on the purchase of foreign diesel engines?

The chief designer of the “Kolomenskoye Plant” Valery Ryzhkov in an exclusive interview with Mil.Press FlotProm called the course for the supply of modern equipment by Western countries a strategic mistake.

Mil.Press FlotProm’s source at the 1st Central Research Institute of the Ministry of Defense of the Russian Federation said that often intermediary firms supply to Russia counterfeit or low quality goods. He added that examples of such practices are found “at every step”.

Aleksandr Simakov, the former head of the Department of Surface Ships Operations of the First Central Research Institute, recalled that the decision of one of the commanders-in-chief to use foreign diesel engines for Russian warships was the pretext for the appeal by a number of industry experts to law enforcement agencies. Simakov called the purchasing of engines abroad a dead-end solution, but at the same time, his estimate is pessimistic for prospects of import substitution of diesels. In his opinion, it is necessary to rebuild the entire production process for success, starting with metal rolling. And give up the Chinese components. Another problem is the actual failure of import substitution in the diesel industry, because up to 80% of components of a number of modern Russian diesel engines are bought abroad.

The “Grachat” Interrupted Flight

The installation of the Chinese diesels Henan TBD620V12 on the anti-sabotage boat Project 21980 “Rook” absolutely did not please the Navy. In September 2016 on the first stage of sea trials in the Rybinsk reservoir, two engines of the lead boat broke down at once. The Chinese diesel is a four-stroke 12 cylinder V-engine with turbocharging and water cooling. Its power is 1630 kW at 1860 rpm. The propulsion system and two diesel generators for the first “Rook” were delivered by the LLC “Marine Propulsion Systems”.

Initially, the boats of Project 21980 were to be equipped with German MTU diesel engines, but after the introduction of anti-Russian sanctions a Chinese manufacturer was chosen.

Often the reason for failure of the diesel engine becomes the incompetence of the crew. The ship repair company NORDWEG told the publication that for diesel engines, especially small ones, it is extremely important to use the right fuels and lubricants, including oil. Such fundamental characteristics as hydrophobicity, so the use of mineral oils. According to the company’s specialist, the best marine diesel engines for small boats are Yanmar and Mercruiser. However, Russian diesel manufacturers will be able to reach their level only in 5-10 years of systems operation.

Another problem is the difficulty in repairing or configuring a number of electronic engine components that are not produced in Russia. We are talking about, for example, the diesel control system. According to the publication’s source in the 1st Central Research Institute, the use of Western “black boxes” is potentially dangerous to ensure secrecy. He added that with similar characteristics of the diesel engine, instead of an electronic control system, a compressed-air operated one can be used. This system is installed on some Russian marine engines. With very close functional characteristics it can reduce the specific fuel consumption in comparison with foreign analogues.

Diesel for “Buyan-M”: Germany-China-Russia?

The small rocket ship Project 21631 “Vyshny Volochyok” was planned to be equipped with the German 16-cynlinder diesel MTU. After the German refusal to continue the supply the project had to quickly order the CHD622V20 diesel from China.

Aleksandr Arkhipov, chief designer of the latest diesel of the PJSC “Star”, M-150 “Pulsar”, explains that the engine from China for the ships of Project 21631 is a licensed copy of the German “civil” marine diesel TBD622, while the manufacturer Deutz-MWM has already left the market. And the Chinese product does not fully correspond to the operation conditions of the Navy, it has “ferry” loads.

As a result, with Chinese engines problems emerged, in particular with turbocharging, and the delivery of the ship was delayed.

On the “Buyan”, an older version of the project, two diesel M-507A/D are installed with a capacity of 10 thousand horsepower each. The power generating systems of Project 21630 ships include derated diesel-gear units (DGU) M507D and the diesel-generator DGAS315. Both products are produced in part by the PJSC “Star”. However, “five hundred seventh” constructively date back to the second half of the XXth century, although they are much more easy to repair.

Along with that, the “high revolution” from “Star” is the worst part of the resource, explained a source in Zelenodolsk plant to the periodical. The designers of the bureau finalised the ship project to ensure the improvement system of the Chinese diesel turbocharging engines “Volochka”. In November 2015, the General Director of Zelenodolsk plant Renat Mistakhov (now head of “Ak Bars”, which has stakes in the company – ed.) said that “Grachata” and “Buyan-M” will receive Russian power generating systems. However, this issue has not yet been resolved.

On August 4, 2018, Mistakhov told the publication that domestic power generating systems for Navy ships are preferable to imported ones: they are easier in terms of maintenance and supply of spare parts.

“The Russian diesel engines manufacturers are equal to the global level, said Mistakhov to the Mil.Press FlotProm journalist. We see how to improve the Kolomensky Zavod (part of Transmashholding – ed.), what efforts directed at the “diesels” are taken by the Kingiseppsky Machine Building Plant (part of the Kalashnikov concern – ed.), “Sinara” (we are talking about the “Star” Plant – ed.). Russian industry is able to produce the latest engines”.

A separate issue is the testing of Chinese engines. The August 7 edition sent an official request for relevant tests to the suppliers of diesel engines from China for the “Buyan-M” and “Marine Propulsion Systems” (MPS) LLC. According to Dmitry Shvets, Executive Director of Dieselzipservice LLC, MPS LLC appealed to his company with a request to confirm to the main command of the Russian Navy the readiness to conduct bench test trials “in order to confirm the stated technical characteristics of the Chinese CHD622V20 engine”. As Shvets told the Mil.Press FlotProm journalist, the specialists of “Dieselzipservice” took part in the meeting under the leadership of the Deputy Commander of the Russian Navy for armament Victor Bursuk on the issue of equipping the MRK Project 21631 with a main power generating system.

“After the meeting, a dimensional drawing of the engine with connecting dimensions was sent to our address for more detailed study to prepare the foundation frame of the bench test, noted Dmitry Shvets. Representatives from “MPS” LLC declined further contact, they did not communicate anymore. We conclude that the CHD622V20 engines tests on the territory of the Russian Federation did not pass”.

At “Dieselzipservice”, they believe that the best engine for the ships of Project 21631 is a diesel M507A. “It is fully domestic, with a long successful operation history. Another suitable engine for such ships is the DM185 (created at the Ural diesel engine plant – ed.), it has not yet been launched in the series, there is no proven record of its operation and repair,” noted the company.

Diesels for the “Coastal Defense Fleet”

Minesweepers and prospective mine defense ships in general should have diesels exclusively as power generating systems, the Central Marine Design Bureau “Almaz” told Mil.Press FlotProm. A high-speed diesel in this case combines efficiency, reliability, sufficient speed and good indicators of low visibility of the ship.

For amphibious ships it is preferable to have “medium-speed”, except for high-speed “paratroopers” on an air cushion, which requires a gas turbine engine (GTE). Medium-speed engines are also good for patrol ships.

One of the good examples of import substitution is the use of domestic diesel engines on the patrol ships of Project 22160. Diesel-reverse-reduction gear DRRA6000 with the diesel engine modifications 16D49 (16ChN26/26) manufactured by the Kolomna plant are used in the power generating system in these ships to work on the propeller of fixed pitch. The press services of the company mentioned this to Mil.Press FlotProm.

The same unit can be used for operations of the propeller on the PSKR Project 22100. The patrol ships of Project 23550 of the Kolomenskoye Plant are also equipped with these engines. The diesel generator 28-9DG with diesel engine modifications 16ChN26/26 is intended for use as the main marine power generating system, and the diesel generator 3-22DGM with diesel engine modifications 8ChN26/26 are used as auxiliary power generating systems.

Diesel engines and diesel generators from “Star” are put on the minesweepers of Project 12700, small rocket ships of Project 2280, and rocket boats of Project 12418 and other units of the fleet. “Star” is one of the largest enterprises of the Russian diesel industry and until recently, it is the actual monopolist in the production of the V-shaped and star-shaped high-speed diesel engines. The article “High Turnover Failure of GOZ: What will give the Fleet Diesel Diversification” is devoted to the state of the enterprises and the prospects in the field of production of “high-speed” engines.

Production and repair of diesel engines of the M-50 and M-500 families, still developed in the Soviet “Star”, is not mastered by any enterprise so in this case the customer has a choice. However, how rhythmically the plants will enter the serial supply of these power generating systems directly depends on the state customer. Ensuring long-term orders is an investment in the quality of the final product, which will never be achieved in a single supply. Consumer products can help speed up the production process in two ways. The first is direct financing of production development through state support programmes or other instruments. The second is in the guarantees of the market in the future, entrepreneurs can independently develop their production capacities.

“Beyond the Sea”: Diesel Engines for Corvettes, Frigates and Large Landing Ships

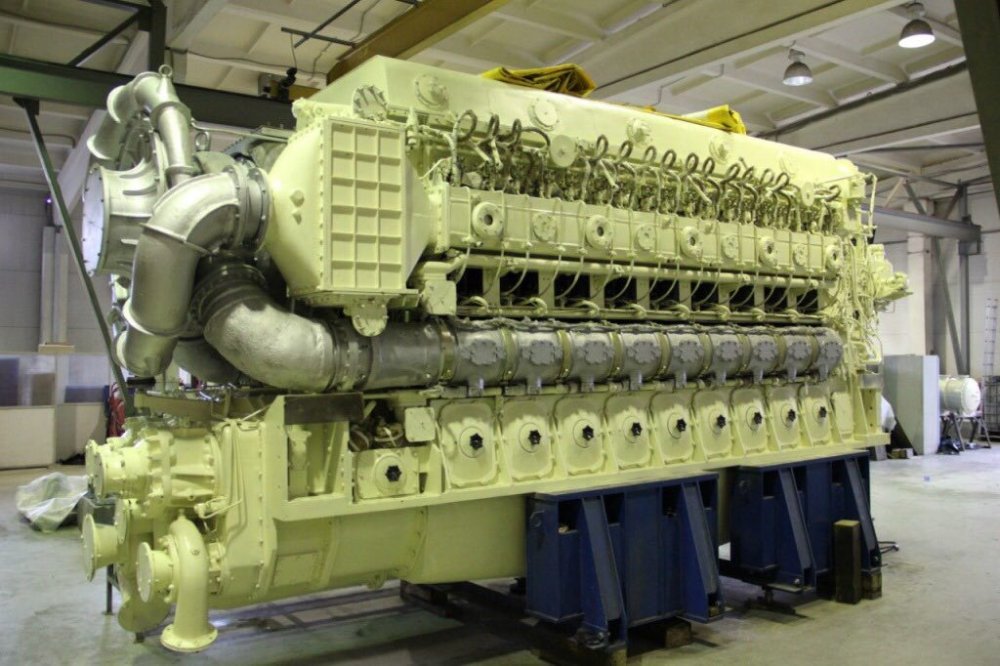

The creation in the early 2000s of a diesel-diesel power generating system for the corvettes of Project 20380 required the cooperation of three diesel plants at once.

The installation of the DDA12000 was created on the basis of the 16D49 diesel from the Kolomna plant, a new gear transmission of the RRP12000 (”Star”) and a diesel-generator unit ADG-630 (UDMS). The upcoming corvettes of Project 30286 will receive a gas turbine engine. One of these units, the M90FRU, is now being building in Rybinsk at the UEC-Saturn facilities.

68b. Kingiseppsky Machinery Plant press service

Although disruptions in terms of delivery of units for EU corvettes occur quite often, in general, the Project 20380 ships’ power generating system can be considered well-developed. Such an opinion was expressed by the commander of the machine group of one of the corvettes of this type to the journalist of the publication. However, he complained about the strong vibration and faulty sensors, as well as the inability of the ship for action in the ocean.

A similar “triple” cooperation was used in the creation of the diesel power generating system DRA35700 for the landing ships of Project 1171. The power generating system consists of two diesel 10G48 from Kolomna, “Star” RRP3700 reducers and ADG-1000 (UDMS) diesel generators. After long headaches with the lead ship’s transfer to the Navy of this project, the landing ship “Ivan Gren”, it was decided to re-configure the engines of “Peter Morgunov”.

State tests of “Gren” began in November 2017, at the end of December, the customer suspended them to solve the identified technical problems, after which they resumed in early April 2018. One of the factory tasks was to solve the problems with reverse gear of the ship. The marine part of the state test of the ship was completed in early May.

Having said so, the coordination between enterprises, especially monopolists in their field, “Star” and “Kolomna”, still leaves much to be desired. Thus, the Kolomna plant in its 2017 annual report reported a decrease in profits due to the failure of “the shipment of diesel-diesel units 1DDA12000, diesel-gear units 1DRA6000 due to late delivery of purchased components” plan.

The Moscow region enterprise’s plans for this year are quite ambitious: the Ministry of Defense has set the plant’s task of manufacturing and supplying 18 diesel-gear units and 18 diesel generators of various modifications for surface ships and submarines.

Perhaps, the public’s close attention was caused by the head frigate’s “Admiral Gorshkov” of Project 22350 tests. Its M55R diesel-gas turbine power generating system was created between 2003 and 2008. The basis of the power generating system, the diesel 10D49 from Kolomna, the gas turbine unit M90FR (”Turborus” from Rybinsk and “Zoya-Mashproyekt” from Nikolaev) with the Ukrainian reducer RO55 and the diesel-generators ADG-1000 (UDMS). In December 2017, the main diesel engine of the newest frigate broke down. The unit production of the Kolomna production plant exposed defects in the connecting rods to the crankshafts, and the hydraulic power unit of “Gorshkov” was corrected in three months of urgent work. Another postponement of delivery of the frigate was not long in coming, however, according to the USC leadership, it was provoked by the unavailability of the “Poliment-Regut” complex.

The Russian fleet imposes great expectations on the domestic production of gas turbine engines for its surface vessels, and the future construction of all large, ocean-going ships depends on its success. Lev Nikonov, chief editor of the magazine “Engine Building” told about this to Mil.Press FlotProm. But the expert doubted the efficiency of manufacturing the first serial gas turbine engines, because they still need to be tested.

According to the publication, four M90FR units are being built in Rybinsk for the Russian Navy ships and another for testing. At the same time, two gas turbine engines for the last two frigates of Project 22350 are ready, now the delivery of the gearboxes is expected. Also a source in the industry told Mil.Press FlotProm that the UEC-Saturn is building three M70FRU engines. They are expected to equip Project 11356 frigates.

The creation of mass production of gas turbine engines is one of the examples when in a relatively short time it was possible to replace Ukrainian products. Another example of rather rapid development of new production is the launch of the new full cycle domestic manufacture of water coolants of type VHD and water-oil coolants of the MKhD type

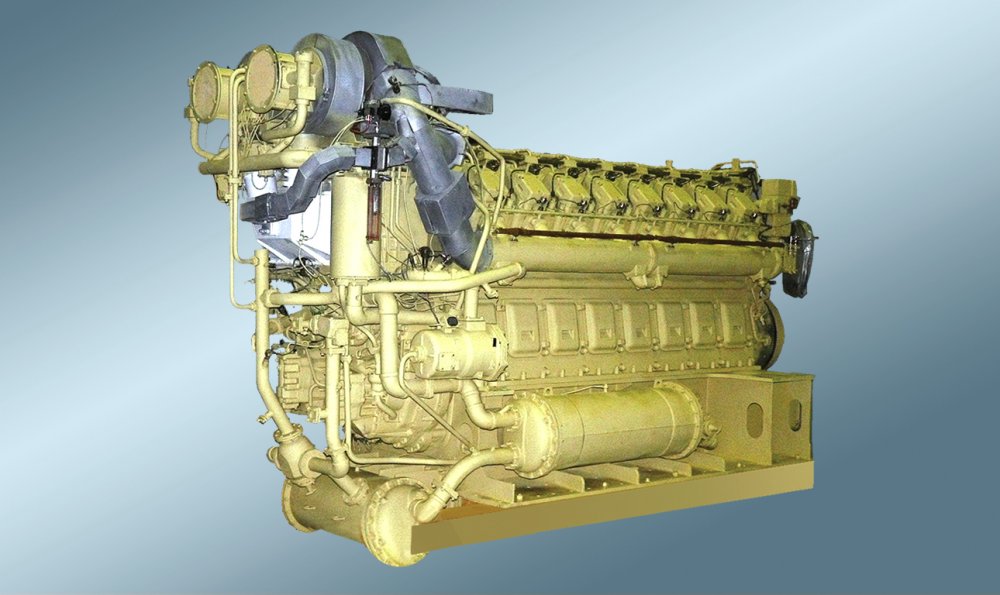

In a number of areas, the domestic diesel industry is gradually restoring its competence. Thus, in 2017, the possibility of manufacturing parts and serial production of marine diesel engines of the M-50 and M-500 families were officially confirmed by the Kingiseppsky machine-building plant. According to the results of a comprehensive audit, the company presented the necessary technological processes for the manufacture of components for marine engines of various sizes, in particular the ChN18/20 and the ChN16/17. The plant is also mastering the production of other engines.

The general director of the enterprise Anatoly Rusin told Mil.Press FlotProm, the plant is appointed as the holder of the authentic documentation of the “Russian diesel” by the joint decision of the Ministry of Industry and Trade and the Ministry of Defense. “The decision was in preparation for six months. It was joint because this type of diesels are applied both in Navy ships and vessels as well as in the nuclear industry, energy, he explained. Thus, our most important task for the near future is the revival of the production of engines of 23×2/30 DPRN dimension, developed at the state company “Russian Diesel”.

However, since the work on the creation of ocean-going ships is not actually underway, to talk about the power generating system for a promising destroyer or aircraft carrier is still pointless. It is much more important to build processes in the creation, modernization and production of diesel engines for smaller displacement ships. At the same time, it is important to maintain a balance between continuous monitoring of the industry and at the same time maintaining a competitive environment in it. The first part of the problem can be solved by creating a conditional “control room for military engines”, which will begin to flow online data on the development and execution of the state defense order.

This will allow time to obtain a signal of problematic areas and send additional resources. Stimulation of industry competition is a much less familiar measure for the national defense industry. Now diesel builders exist in a vacuum of natural monopolies, and shipbuilders do not have enough leverage to influence them in the event of problems with the failure of deadlines and quality. To reduce the risks of postponing the timing of the renewal of the Russian fleet through the domino effect, when a whole ship gets stuck at the shipyard due to the power generating system, the diversification of the distribution of orders for new project developments and final products, will be possible.

I am certain that Russian engineers will overcome these problems.

I am also reminded of the four new British destroyers that are having the sides of the ships cut away to allow removal and replacement of the engines that fail in hot climates. Such as the Mediterranean Sea :)

i am certain too:)))

“I am certain that Russian engineers will overcome these problems.”

How you dare.

Don’t you know they got no funds.

Don’t you know they spent all of them on vodka, and even that there are bears running free around the cities.

Oh I forgot that Russia ‘ Is only a gas station ‘ with no technical abailiies.

Silly me :)

I’m not a fan of communism but the fall of the USSR was one of the greatest tragedies in our time.

Gorbachev’s kindness was used to make life miserable for the Russian people.

Kindness is not an apropriate word for a traytor.

‘Traitor’s’ are rarely forgotten when real historical facts are written Tudor.

No more funds in summary to make another revitalization project. Make sense though. They’re doing great with other project despite their Syria deployment.

So Russia forgot how to make diesels! Oh dear, oh dear, they once made some very good ones for vehicles, whereas shipbuilding ones the the Danish B &W were king, bought up by MAN. But they still sail and are still being build.

I am a marine engineer.

Rolls royce and wartzila is much better option

There must be some persons working for these diesel engine companies who have some brains and would like to be the boss and run things properly and make money. Give them some business loans, help them to hire the now unemployed Ukrainians to come to work in Russia, the ones who made the diesel engines in Ukraine before the coup. Kim Jung Un did it with the missiles for his nuclear program with great success, so I am sure Russia can do the same for Diesel engines.

If this guy it I am sure mother Russia can ado it

https://www.youtube.com/watch?v=qHkWv1vHtHk

JP 54, D2, and D6 EN590,JET A1 AVAILABLE ON FOB DIP AND TEST IN SELLER TANK

We Can supply Aviation Kerosene,Jet fuel (JP 54-A1,5), Diesel (Gas Oil) and Fuel Oil D2, D6,ETC in FOB/Rotterdam only, if you want in Rotterdam buyer must own tanks in Rotterdam serious buyer should contact or if you have serious buyers my seller is ready to close this deal fast contact us below:now base email us (omelchenkodmitry@inbox.ru)

PRODUCT AVAILABLE IN ROTTERDAM/ CI DIP AND PAY IN SELLER EX-SHORE TANK.

Russia D2 50,000-150,000 Metric Tons FOB Rotterdam Port.

JP54 5000,000 Barrels per Month FOB Rotterdam.

JA1 Jet Fuel 10,000,000 Barrels FOB Rotterdam.

D6 Virgin Fuel Oil 800,000,000 Gallon FOB Rotterdam.

Contact Person:Feliks Andros

Company: OOO “LK SINTEZ”

Email: omelchenkodmitry@inbox.ru

Skype: omelchenkodmitry@inbox.ru

Phone: +7-926-80-156-31,

English Department

Best Regards